How To Install Crown Molding With Led Lighting

Is cove lighting right for you?

You lot may recollect your ceiling looks expert at present, but when the cove lighting rakes across the surface, you may detect seams and blast pops you lot never knew existed. Stand up on a ladder and shine a flashlight across the surface of the ceiling. If your ceiling is ugly or damaged, y'all may desire to abandon the idea or build a cove that washes the walls with light instead.

Our cove lighting design

Our cove is congenital from crown molding and set ii in. downwardly from the ceiling. We installed the crown on top of a baseboard to create a wider space for the light, and tacked a small cove molding onto the lesser of the base of operations to finish information technology. We fastened a LED calorie-free strip to the wall and then the lights would rake across the ceiling, and in order to maximize the calorie-free, we kept the strip as high equally we could without its being visible from the ground.

Brand a small mock-upwardly and experiment with dissimilar positions for the cove and lights. Every room is different, and the cove nosotros made may not be the best style for your room.

Paint first

It'due south easier to pigment all the cove parts before you install them. Touching up a few nail holes after installation is a lot easier than taping off unabridged walls. Painting the part of the wall that volition exist seen above the cove will help tie everything together. Cull either the color of the ceiling or the color of the cove. Lighter colors reflect more lite, so paint the back of the cove components as well.

Choosing LED Lighting

It's very of import to think of low-voltage LED lighting every bit a 'system.' Transformers are available in 12-volt, 24-volt, magnetic, nonmagnetic, dimmable and nondimmable. The transformer, strip lighting and dimmer switch all need to be compatible.

You'll also have to consider how much lighting you need. Two transformers may be required for large rooms because each transformer tin merely provide power for a specified length of strip lighting. The lights at the end of a long run will be dimmer than the others if hooked up to an undersized transformer. White light is most often used in commercial settings or outdoors, while warmer colors are preferred for homes. Brighter (more than lumens) strip lighting costs more than only is a adept selection. Strip lighting that is run at less than full power will last longer. Some lighting systems tin last upwardly to 50,000 hours.

Your all-time bet is to stop in at a lighting shop, or call an online retailer, and explain the dimensions and layout of your room exactly. Nosotros bought our lighting from LED WORLD. The staff were extremely helpful in presenting our options and making sure nosotros had all the proper components to cease our project.

Other Lighting Options

LED lighting isn't cheap. A system like we installed costs $9 to $fourteen per ft. for 22 ft., merely less expensive options are available:

Plug-in LED strip lighting

Home centers sell strip lighting with a prewired transformer. These would work well for shorter runs but need to exist plugged into a receptacle hidden behind the cove. They can be wired to a regular switch, simply the dimmer is located on the transformer, which won't be easily accessible. $viii per ft. for 8 ft.

LED rope lighting

The cheapest selection by far is to install an LED rope light. Rope lights are not low-voltage, and they can be run long distances and dimmed with a regular dimmer. On the downside, they cannot be cutting to size or separate off in more one direction; it'due south harder to direct the light; and the light is about i-third every bit brilliant and tends to exist a little blotchy depending on where information technology'south placed. Rope lighting would also require a receptacle behind the cove. $2.75 per ft. for xiii ft.

Blueprint Your Own Cove

You don't have to build your cove exactly the way we did. Hither are a couple culling styles:

A Simple Cove

This piece of cake-to-build, easy-to-install cove is made from 3/4-in. MDF ripped to size on a table saw. Countersink the screws. Fill the holes and touch up the seams with woods filler or surfacing compound.

Valence Style

Shine lite both on the ceiling and down the wall with this valance-style cove. This one is made from straight 3/4-in. clear pino. The sharp edges of the valance take been softened with a router fitted with a one/8-in. round-over bit. Install the T-shape base of operations to the wall first and then fasten the valance to the base. Plan to buy twice as much lighting.

Step 1: Mark the wall

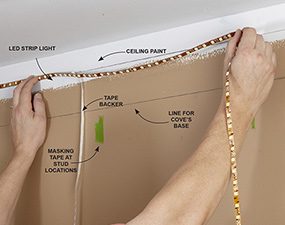

Depict reference lines to betoken the bottom of the light strip and the lesser of the base. Don't worry whether the lines are level. Instead, measure down from the ceiling in several places and connect the dots to achieve a consistent distance between the cove and the ceiling. Years of settling tin throw a ceiling out of level. A cove not in line with the ceiling will create a noticeably uneven gap. Salve fourth dimension by cutting a couple blocks of wood to utilise equally marking gauges before installing LED strip lights.

Stride 2: Install LED strip lights

When yous're placing the LED strip on the wall rather than within the cove, information technology'south easier to install nigh of it before the cove is up. Begin at the point of the room where the transformer will be installed. Leave the record backer on the first few feet of the LED strip so it tin can be pulled away from the wall when it comes time to connect it to the transformer.

The record on the dorsum of the strip is super gummy. One time it's on the wall, information technology's tough to remove without pulling off the paint along with information technology. To start, press the strip to the wall in i spot, hold it there, pull the record out a couple feet, and press it to the wall at that point likewise. Do this a few times in a row, and check to run across if it's straight. If information technology is, go back and press the residuum of the tape tight to the wall. Strip lights similar these can be cut to size but simply in sure intervals, usually two to 4 in. There will be conspicuously marked cutting lines on the strip.

Step 3: Build the cove

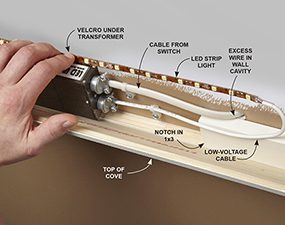

Secure the base of operations to the wall with 2-in. screws into every stud. Self-tapping trim-head screws piece of work great. Keep the screws high enough so they go covered past the crown. Depending on the size of the transformer, y'all may need to notch out a department of the base to make room so it's not visible from the flooring.

Cut blocks to support the crown. I piece of cake fashion to figure out the angle for the blocks is to concord a department of crown next to your table saw bract and adjust the bract to the same angle as the crown. Rip a 2×4 at that angle. Earlier installing the blocks, indicate with a marking which way is up. Stagger the blocks near every 16 in. or and then, and fasten them with 2-in. 18-gauge brads.

Working with cove molding can exist tricky, and in this article, nosotros don't cover all the techniques for measuring, cutting and coping when installing molding. DIY University offers a course on crown molding.

Finish up by installing the small-scale cove at the lesser. Spike the cove with 1-1/4-in. brads angled upwardly into the base of operations.

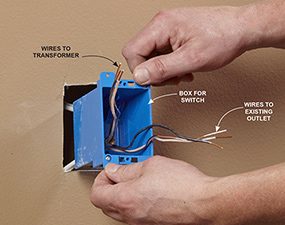

Stride 4: Fish the new cables

Pick an existing outlet on an interior wall to pull power from and then you don't take to deal with insulation when you lot fish the new cables. At that place's a adept gamble the existing electrical box may not exist big enough for additional wires, so programme to replace it with a larger twenty-cu.-in. remodel box (sometimes chosen an 'old work' box). Removing the existing box also makes it easier to fish in the new cables. Shut off the power, then poke a hacksaw blade on either side of the existing box to find which side the stud is on, and cutting out the nails that concur information technology in place. If this kind of DIY electric work is intimidating, yous could learn all you lot need to know past taking a few electrical courses in The Family unit Handyman's DIY University.

Apply the remodel box every bit a template to cut a pigsty in the wall for the new light switch. At that place'south no need to cutting the hole next to the stud. Remodel boxes are held in place with wings that clench onto the back of the drywall. Cut the pigsty for the switch box with a jab saw or utility knife at the aforementioned meridian equally the other switches in the room. Fish the new cable from the switch box hole down and out through the existing hole below information technology. Put a slight bend on the cable so it hugs the back of the drywall, which makes it more hands attainable.

In this commodity, we used a transformer that is hardwired, then an outlet box wasn't necessary. We just had to drill a 3/4-in. hole in the drywall above the cove and run a cable down to the switch. There are other lighting options that may require an outlet to a higher place the cove. The procedure is the same as the adjacent step; just be conscientious to place the new outlet so it's completely hidden behind the cove. It will besides assistance to install a recessed outlet box for the light'south power cords.

Whether you install an outlet, exit a few feet of cable sticking out of the wall at the top. That will go far easier to wire the transformer. The excess cable tin be pushed back into the wall cavity afterwards the connections have been made.

Be generous and remove 10 in. of the cable'south sheathing and strip the end of each wire earlier pulling them into the box. Make sure there's at least 1/4 in. of capsule extending into the box and three in. of wire length extending beyond the confront of the box. Don't over-tighten the box onto the drywall or you could strip the screws or damage the portion of the drywall that holds it in place.

Pace five: Consummate the connections

The existing receptacle will need to be replaced with one that is both tamper resistant (TR) and protected with an AFCI (arc fault circuit interrupter). AFCI interrupters protect homes from fire and are now required in most locations of the home. The AFCI has 'line' and 'load' terminals and cannot be connected with 'pigtail' wires like the existing outlet may take been.

It's extremely important for the dimmer switch to be compatible with the LED light strip yous install. You need a 'depression-voltage' uniform switch, not an 'LED' uniform switch. The wrong switch will cause the lights to flicker or non work at all. We used a Lutron switch recommended by the lighting supplier.

Transformers come in many shapes and sizes. Follow the wiring directions on your particular transformer. Once the transformer is connected, slide the excess cable back into the wall cavity and cease securing the strip low-cal. Stick the transformer to the wall with Velcro strips if information technology won't stay in place, and install cable straps with drywall anchors.

Step 6: Install the crown

Fasten the bottom of the crown to the base every 16 in. with 1-ane/4-in. eighteen-gauge brads. Secure the center of the crown to the blocks with two-in. brads. To avoid nailing through the tops of the blocks, aim the gun straight in toward the wall rather than angling information technology up toward the ceiling. You don't want to poke yourself on an exposed brad or impairment the calorie-free strip with a wayward shot.

All that'due south left is to flip the power dorsum on and plan that dinner party so you lot can show off to all your friends.

Required Tools for this Projection

Have the necessary tools for this DIY project lined up before you get-go—you'll save fourth dimension and frustration.

Source: https://www.familyhandyman.com/project/how-to-install-elegant-cove-lighting/

Posted by: beamonshent1951.blogspot.com

0 Response to "How To Install Crown Molding With Led Lighting"

Post a Comment